Frequently Asked Questions (FAQ)

Why choose IR Inspect?

When does it make sense to perform a thermographic inspection of a solar power plant?

A thermographic inspection is useful in several situations—especially if you have noticed a decrease in electricity production or simply want to check the actual condition of your photovoltaic modules.

Drone-based inspections using infrared cameras reveal faults and damage that cannot be detected with the naked eye.

During the analysis, supported by artificial intelligence, all detected anomalies are categorized according to fault patterns and severity levels and precisely located within the power plant (string, array, module).

The result of the inspection is a detailed report showing defective modules and their exact positions, significantly simplifying maintenance and repair processes.

In addition, this type of inspection helps increase efficiency and extend the lifespan of modules by identifying temperature differences and potential “hot spots” in time, which—if left unresolved—could lead to permanent damage.

Can thermographic inspections detect faults early and extend the lifespan of solar modules?

Yes. Thermographic analysis provides valuable insight into the technical condition of the system, as well as into faults that may affect its efficiency and safety.

In this way, it is possible to identify faulty cell strings caused, for example, by poor connections and prevent long-term power losses.

In addition, this type of inspection can reveal damage caused by external factors such as hail, lightning strikes, or overheating, enabling timely intervention and preventing further damage.

Regular thermographic evaluations contribute to p

Is a thermographic inspection useful before purchasing a solar power plant?

Yes. If you are planning to purchase a solar power plant, a thermographic inspection provides transparent insight into the actual condition of the modules.

The inspection is carried out module by module, and the report includes a tabular overview of all detected anomalies within the array.

We use state-of-the-art drone technology and high-resolution thermal imaging cameras, with footage processed in advanced software that automatically detects thermal irregularities and precisely links them to specific modules.

The inspection results are presented in a clear and well-structured report with recommendations for any corrective measures, enabling you to make informed decisions before the purchase.

Can I obtain documentation for selling a solar power plant?

Yes. Detailed thermographic inspections provide the information needed by both buyers and sellers.

The analysis and assessment of module conditions allow buyers to objectively adjust their offers, while sellers can address identified issues in a timely manner and document them, thereby increasing the value of the power plant during the sale.

Our team of certified professionals prepares technically reliable and standardized reports, contributing to transparency and trust throughout the entire sales process.

What if the manufacturer’s warranty on my solar modules is about to expire?

Regular thermographic inspections are essential for the timely detection of faults and for preparing the documentation required to exercise warranty rights.

IR Inspect conducts all inspections in accordance with the international IEC 62446 standard, ensuring the accuracy and reliability of the results.

The collected data can serve as a basis for initiating warranty claims or for planning necessary repairs before the warranty expires.

Which anomalies and fault patterns can be detected through a thermographic inspection?

Thermography can detect various types of faults, including:

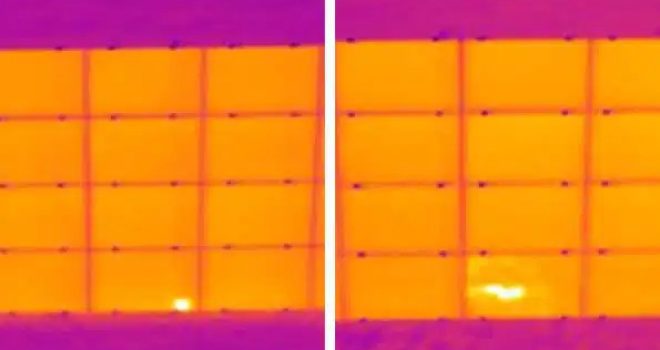

Cell damage and “hot spots”

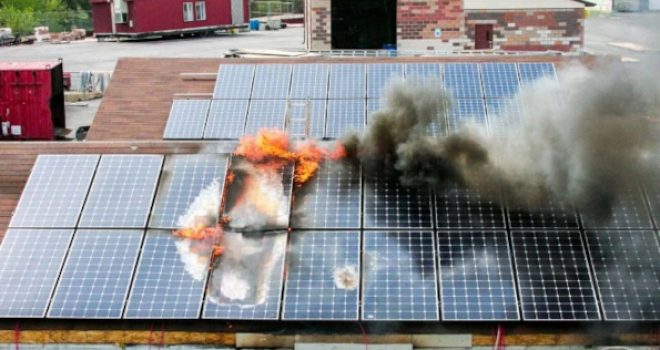

Cracks and microfractures in cells can cause inactive areas within a module, resulting in reduced efficiency. Such damage creates localized overheating points (“hot spots”), which generate high thermal stress and may lead to module failure or even fire hazards. In cases of these faults, a power loss of up to 10% per module can be expected.

Faulty cell strings

This anomaly occurs due to inactive cells, connection faults, or malfunctioning bypass diodes. Thermographic images clearly show temperature differences between cells connected in series. Such defects can cause power losses ranging from 30% to 60% per module and require timely diagnostics.

Potential Induced Degradation (PID)

PID (Potential Induced Degradation) leads to a gradual reduction in the efficiency of solar modules, with losses reaching 30% or more after several years of operation. In thermographic images, PID is identified by elevated cell temperatures, most commonly along the edges of the modules.